Material and energy flows in the Polish industry

At the Together for a circular economy “oto-GOZ” project summary organised by the Polish Ministry of Economic Development and Technology, Refficiency’s Jonathan recently spoke on material and energy flows in the Polish industry.

Poland is the sixth largest producer of GHGs in Europe due to it being a large energy and material user with a strong industrial sector. Poland is the third largest producer of cement in Europe and the fifth and sixth largest European producer of steel and plastic respectively.

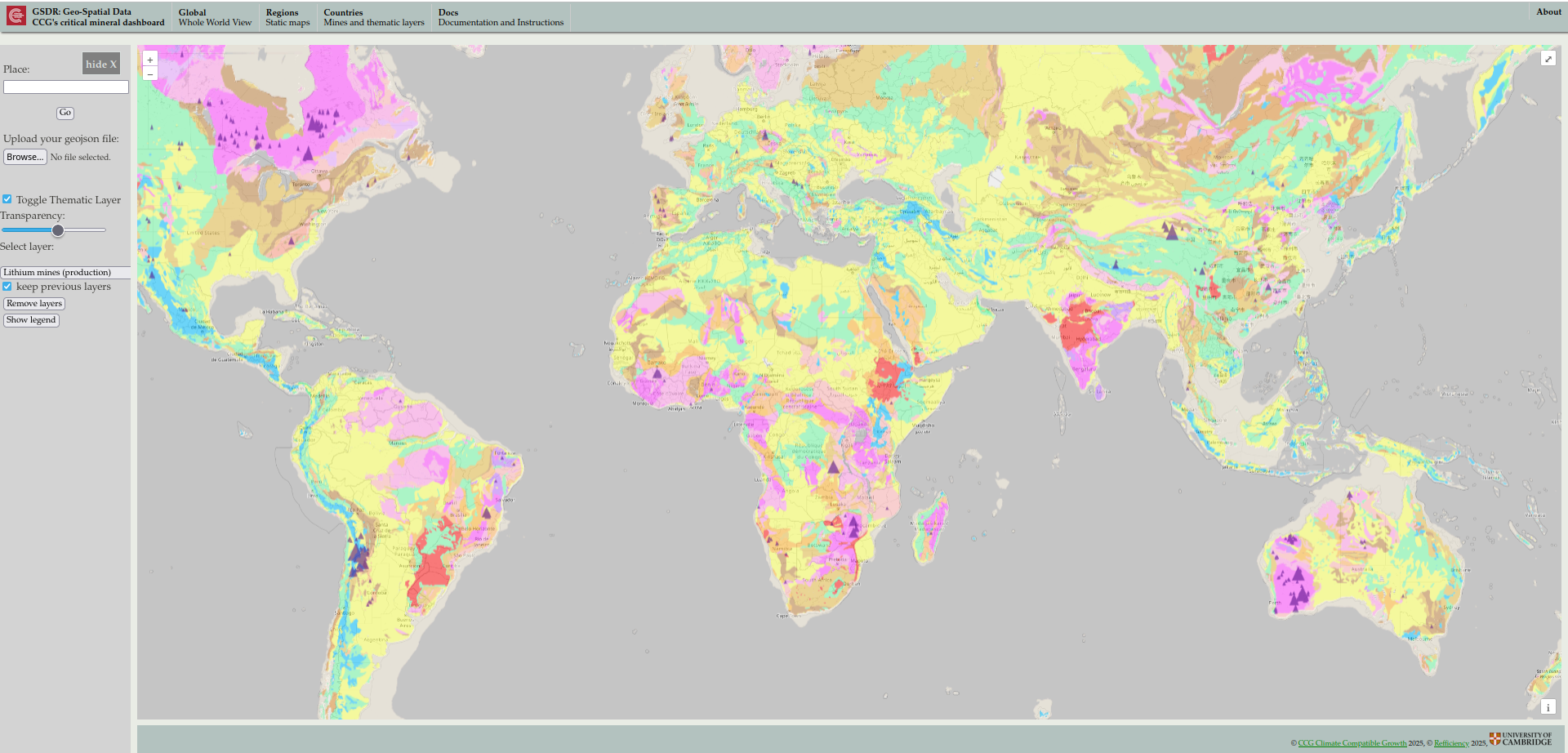

In the talk, Jon showcases his team’s previous 2018 mapping work, where the energy and material flows of five key industries in Poland were mapped. Part of this work included a map which shows energy and material flows together using exergy analysis. A second report has just been completed to update previous mapping work using more recent 2019 data and a much wider collection of industrial sectors.

The mapping process is critically important for connecting the goods and services that people desire, back through the industrial supply chains, to the carbon emissions that are emitted in the making of these products. We can think of resource efficiency in a simple Sankey diagram where we have resource input (material and energy) on one side and useful products, useful by-products, waste products and losses on the other – resource efficiency being the useful output compared with the resource input.

The next steps in this work are to advance mapping throughout the sectors using exergy, enabling material and energy to be put on the same footings. Using resource flows for the waste flow in Poland could lead to proposed interventions to close the circular economy gap in Poland. In addition, to map the flow of GHG emissions themselves to identify where the largest contributions of GHGs come from and hence where the biggest areas of improvement could be.

Watch the whole talk on INNOWO’s YouTube channel below

Photo credit: Dimitry Anikin