Transforming agrifood production systems and supply chains with digital twins

Agriculture is a vast global industry, but it is also incredibly wasteful, exceeding several planetary boundaries whilst still leaving almost a billion people undernourished. Scott Jeen from Refficiency has published a review of the role of digital twins in creating a more sustainable future for global agrifood production systems, alongside Asaf Tzachor and Catherine Richards.

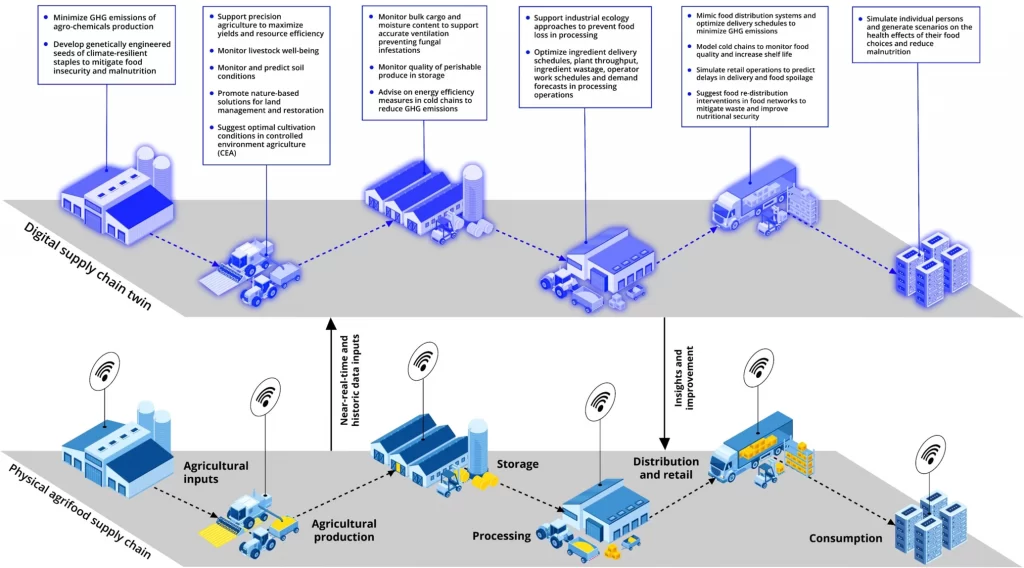

Their abstract reads: “Digital twins can transform agricultural production systems and supply chains, curbing greenhouse gas emissions, food waste and malnutrition. However, the potential of these advanced virtualization technologies is yet to be realized.” The authors consider the potential and limitations of using digital twins across six steps in the agrifood supply chain.

What are digital twins, and how might they help transform the agricultural sector?

A digital twin is a computer-simulated virtual representation of a physical thing. In 2020, the European Space Agency unveiled an ambitious project to create a digital twin for the entire planet. Advanced sensing technologies allow the biological, chemical, and physical properties of objects to be monitored in real time and replicated in their digital twins. These simulations offer opportunities to model not just the current state of a physical object or system, but also to simulate the impact of potential future changes. Digital twins can therefore promise opportunities to assess how the global food system might respond to new policies, strategies, or technologies. The potential benefits of using digital twins to model agrifood production systems and supply chains are represented below.

‘Live’ digital twins offer a way to simulate crops, farms, agricultural equipment, storage facilities, processing factories, and distribution networks. However, the authors identify and discuss four key techno-economic limitations currently associated with their deployment.

Four key barriers to the deployment of digital twins

The first challenge they identify is achieving sufficient sensor coverage and quantifying uncertainty. Digital twins are used in combination with advanced decision-making systems to predict what might happen in the agrictultural system and recommend the best strategies for achieving industry goals. For example, a digital twin of a storage facility may be used to predict food spoilage. However, in order to predict this accurately, a large number of factors need to be monitored, such as the temperature, type, and age of the food in question. Even if there is complete sensor coverage, digital twins, like all models, can only ever be approximations of the physical reality. This means that their ability to accurately represent the present state of the system, and to predict the future, are always uncertain. Understanding and capturing this uncertainty remains an urgent challenge for the research and deployment of digital twins.

It is also extremely difficult to create a ‘live’ digital simulation of the vast supply chains involved in agriculture that include food-redistribution centres like food banks and soup kitchens. Monitoring these centres would require large investments, which the corporations pioneering R&D into digital twins might be unwilling to make since they do not yield direct profits.

Secondly, digital twin technologies currently rely on a structure of data reporting that, in practice, contains gaps and inconsistencies. Sensors sometimes fail, or do not log data for period of time. This means that there is an imperative to design digital twins that are not thrown off course by periods of time when sensor data is inaccessible, a challenge which will require technological innovation.

Thirdly, as with other simulations, digital twins can be affected by modelling flaws introduced in the design and coding processes. It is always possible for human errors to arise as modellers create and merge codes and algorithms to try to represent complex, real-world physical realities. If these are missed, there could be implications for the types of action that are recommended by the decision-making systems that make use of the digital twins.

Finally, there are currently no formalised or common modelling standards for digital twins. This could lead to difficulties when researchers try to integrate separate models which may not be compatible with one another. For example, issues could arise if different measurement systems are used; there is extra work needed to combine virtual simulations of equipment and facilities that monitor temperature in Farenheit compared to those using the Celsius scale.

The authors conclude that whilst digital twins hold promise for the future sustainability of global agrifood production systems and supply chains, the barriers and limitations to their effective scaled-up deployment and are significant. They recommend significant research into tackling these barriers and studying how the drawbacks and uncertainties discussed above affect the digital twin technologies that are already being deployed. They assert that this is a scientific challenge, but also an organisational and politico-economic challenge. Different stakeholders will have to work hard and collaborate across disciplinary and wealth boundaries to ensure that this technology delivers genuinely equitable and sustainable outcomes for the agricultural industry.

Read the full review by Asaf Tzachor, Catherine Richards, and Scott Jeen here: Transforming agrifood production systems and supply chains with digital twins.

Photo credit: ThisisEngineering RAEng