Criteria for Assessing Sustainability of Lignocellulosic Wastes: Applied to the Cellulose Nanofibril Packaging Production in the UK

New paper from Samantha Islam and Jonathan Cullen outlines 13 criteria for assessing the sustainability of lignocellulosic wastes, a new source of cellulose nanofibrils for producing bioplastic packaging.

What are bioplastics?

Bioplastics are a popular solution to the high profile issue of plastic pollution and emissions. They are bio-based and biodegradable, unlike conventional plastics, which are produced from fossil fuel feedstocks and endure in the natural environment. Global production capacity for bioplastics is set to increase from 2.23 million tonnes in 2022 to 6.3 million tones in 2027.

What are the pros and cons of using bioplastics?

✅ Avoids emissions from extracting fossil fuel feedstocks

✅ Bioplastics often biodegrade, avoiding pollution of soil and the oceans

✅ Plant matter used as feedstocks sequesters carbon during its lifespan

❌ Often made from food crops, meaning high cost and competition for resources and implications for food supply

❌ Growing these feedstocks also increases land and fertiliser use (fertilisers are a major global source of emissions)

❌ Often have less desirable properties. Bioplastics are often less effective at preserving food, and the emissions that result from food spoiling quicker can be significant.

New sources of feedstocks for bioplastics

To tackle these challenges, our S2UPPlant project is exploring using secondary feedstocks (e.g. leftover or waste biomass from agricultural, arboreal and industrial activities) to produce bioplastics. This could mean wheat straw, fallen conifers, or even waste paper/cardboard.

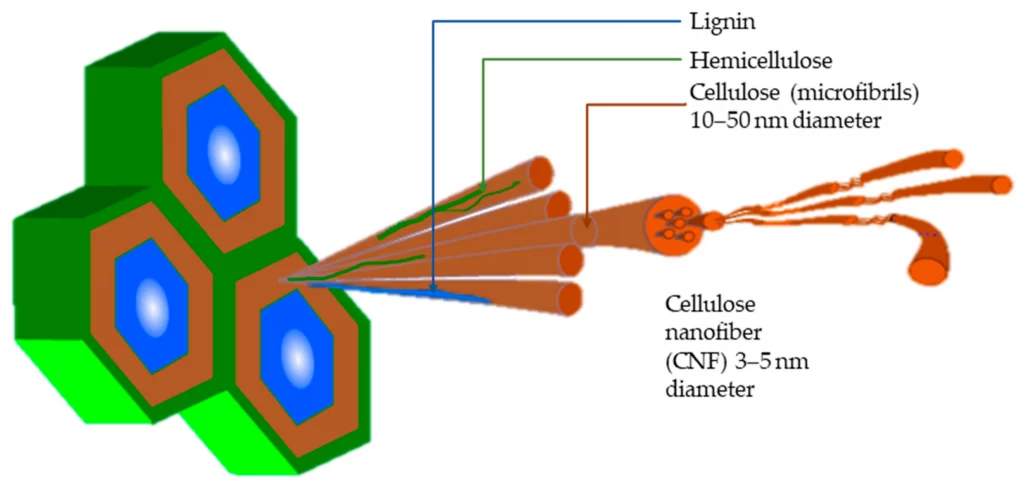

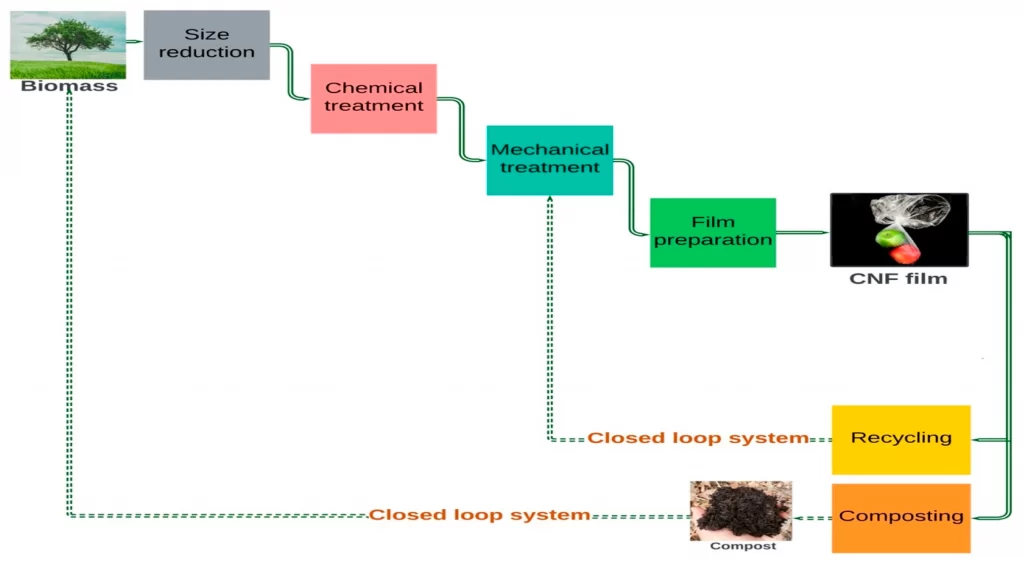

The bioplastic is produced from lignocellulosic waste and residue, which is chemically and mechanically treated to produce cellulose nanofibrils (CNF). These can be made into film as an alternative to plastic food packaging. By using waste biomass instead of new crops, these bioplastics avoid the detrimental impacts of intensive land use and fertiliser application. Bioplastics produced this way also avoid competing with the food and biofuel industries when sourcing their feedstocks.

Assessing the sustainability of lignocellulosic wastes

This new paper proposes criteria for determining which feedstocks are the most suitable for producing celluslose nanofibrils to use in packaging. Many of the types of lignocellulosic waste and residue have alternative uses (e.g. straw being used for power generation or animal bedding), or go through different end-of-life treatments (e.g. incinerating paper waste). If we are going to divert these materials to produce CNF film, we need to first evaluate how economically viable and environmentally sustainable they are as bioplastic feedstocks. This study pulls together 13 criteria to evaluate the sustainability of lignocellulosic waste and residue feedstocks, based on an intensive literature review and expert interviews.

13 criteria for sustainability:

- Availability (How much of the material is available to use?)

- Physical composition (Are the materials raw or processed? Homogenous or mixed? More processed waste streams create films with less tensile strength, and mixed wastes may be more expensive to use.)

- Cellulose (Higher cellulose content results in greater yields and better tensile strength)

- Hemicellulose (Higher hemicellulose content increases CNF yields and can result in enhanced properties, including recyclability)

- Bulk density (Materials with greater density take up less space and incur lower transportation costs)

- Lignin (Lower lignin content makes it easier to extract CNF, because lignin causes biomass to be recalcitrant to chemical degradation)

- Ash – the inorganic constituents of biomass e.g. salts of elements like nitrogen and potassium (high ash content indicates less durable biomass, and dealing with ash content can be costly)

- Particle size (smaller particle size needs less time and energy to extract CNF, and increases bulk density, meaning it is cheaper to transport)

- Cell wall thickness (High cell wall thickness means more energy is required to extract CNF)

- Price (High costs can be a significant barrier to large-scale development)

- Seasonal variability (Some agricultural residues, such as straw, are impacted by seasonal variation and so are not consistently available)

- Environmental emissions (Waste streams that have higher emissions across their lifecycle are less environmentally sustainable)

- Soil and biodiversity impact (Forest-/agriculture-based wastes are habitats for microorganisms, fungi, insects and birds, so excessive extraction of these types of biomass would reduce soil quality and biodiversity)

Applying the criteria to the available lignocellulosic waste and residue streams revealed their differential technical, economic, and environmental suitability for bioplastics production:

- Paper and cardboard waste have the highest availability, but may result in lower quality bioplastic film.

- The highest mechanical properties were derived from wood residues and wastes, but high process energy consumption and costs to biodiversity and soil quality will be a barrier to their use.

- Using secondary waste streams (material that would be incinerated or landfilled) reduces feedstock cost and local environmental impacts, but incurs high processing costs because of the heterogeneity of the materials).

The criteria will help identify which feedstocks are both economically viable and result in emissions savings. The study will support the development of low-emission bioplastics and encourage the creation of a circular bioeconomy.

Read the full paper from Samantha and Jonathan here: Criteria for Assessing Sustainability of Lignocellulosic Wastes: Applied to the Cellulose Nanofibril Packaging Production in the UK